Established in 1987, DielTech specializes in advanced adhesive solutions, predominantly serving the medical device industry. Over the years, DielTech has accumulated unparalleled knowledge and experience, enabling custom-made solutions for clients – always adhering to the highest standard.

OUR APPLICATIONS

Adhere to Skin

Adhere to Device

Adhere Skin & Device

Precise Cutting and Assembling

OUR TECHNOLOGY

At DielTech, we consistently work to upgrade and improve technology. Striving to improve our already Hi-standards.

Using the most up-to-date technology, we provide our customers with customized adhesive solutions.

Die-Cutting Methods

- Precision flat cutting.

- Rotary cutting for accurate edges.

- Cutting rolls into different widths.

- Laser cutting for creating models.

- XY cutting to create models from raw materials.

- Hybrid integration cutting.

Coating Methods

- Full adhesive coating on a variety of materials.

- Selection adhesive coating on predetermined areas.

- Adhesive-coating on different raw materials.

- Silicone sheet coating on a variety of sizes and parameters.

Finishing Methods

- Flexo printing.

- Heat stamping for matte and glossy finishes in an assortment of shades and sizes.

- Welding for powerful, long-term, and weather-resistant solutions.

- Sophisticated folding for reusable seal solutions.

Process Management

Your Idea

Brainstorm with our engineering team.

Design

Our team creates a functional design according to your requirements and specifications.

Planning & Modelling

Using the SOLIDWORKS program, we develop your design into a model.

Finalization

Physical models are made, ready to receive your approval.

Scaling

Your design is ready for production!

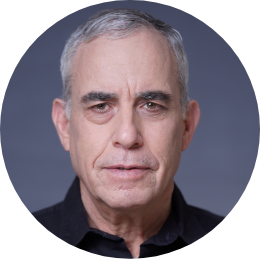

Our Team

Our Partners

Contact us

+ 972 8 9432090

6 Hidekel Street, Yavne, Israel

diel@diel.co.il

LinkedIn